Reliable and powerful

The first electrically operated ceramic infrared heater, after the discovery of IR radiation in 1800, was developed by Elstein-Werk in 1950. Since the availability of this development as an industrially useful product, numerous production processes have to this day switched to Elstein ceramic heaters.

Perfectly designed Elstein products will continue to fulfil the growing demands of all areas of industry well into the future.

Example Edison

A patent is issued in 1949 for the first infrared heater worldwide with a complete ceramic radiating panel. Elstein-Werk is founded in 1950 on the basis of this invention, which is still current to this day.

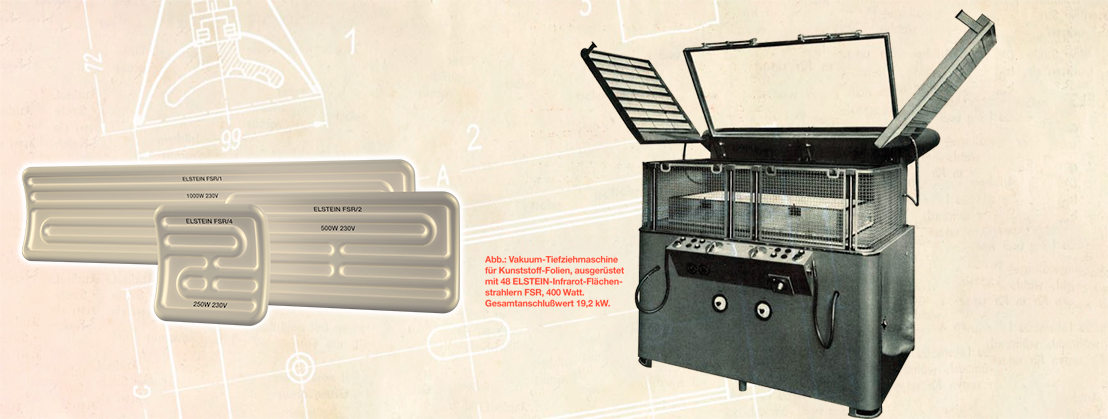

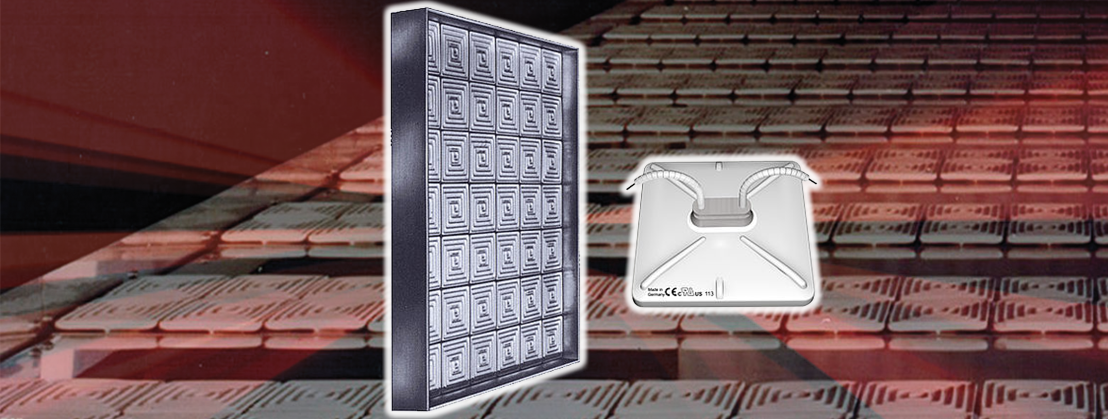

First Panel Heaters

By the development of the FSR panel heater, Elstein-Werk enables industrial users to heat or dry large-surface materials using IR radiation.

Rod Heaters

The rod-shaped Elstein heaters now make it possible to selectively heat a product.

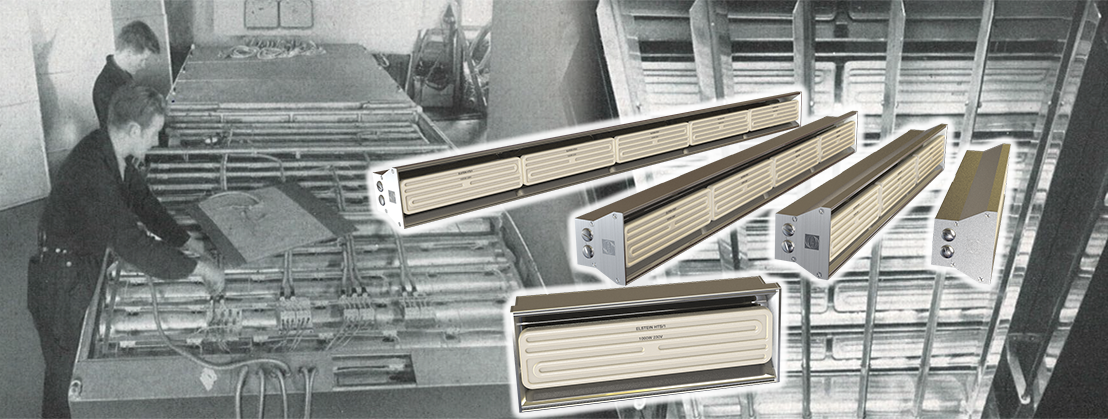

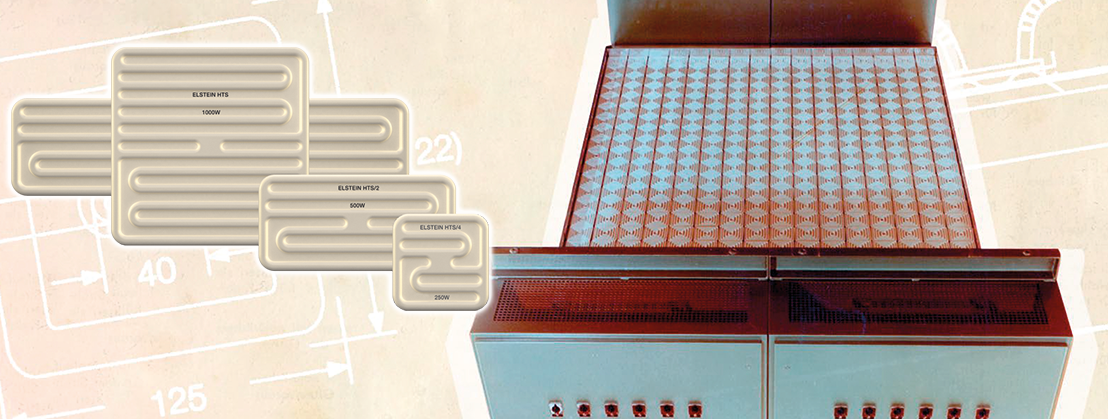

First IR Construction System

From the very beginning, the EBF construction system reduces construction costs for machine and plant construction.

Installation-ready heater bars are available in different lengths.

Internal Insulation

The crucial new feature of this panel heater is a closed cavity between the radiating panel and back piece. The air present in the cavity is thermally resistant and reduces the temperature in the wiring space of the heating panel.

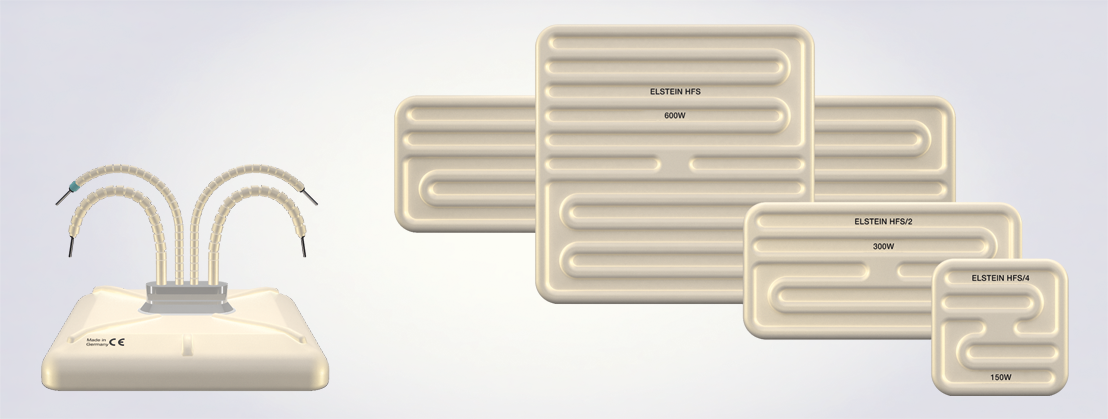

Mounting Rail System

A special aluminum profile, polished reflectors, and side walls of different lengths are the essential elements of this new construction system.

The system is designed for the installation of HFS heaters and can be delivered as a completely mountable heating panel.

Energy Saving

Heaters with internal insulation have not yet exceeded a power density of 51 kW per m².

Only the use of the latest ceramic materials combined with the installation of an internal solid insulation inside the heater enable the HTS heater to make a quantum leap to a power density of 64 kW per m².

Incidentally, energy savings of up to 20% are achieved in comparison to solid heaters.

High Performance

From room temperature to a 1,000°C operating temperature in less than a minute and a panel power of up to 76 kW per m² - these powers are unmatched to this day for large-surface, fully ceramic heaters and are therefore completely unique to Elstein.

SHTS and HLS. Masters of high temperatures.

Heat in-time

IR heaters with short reaction times are built to match short machine cycles. Numerous materials do not sufficiently absorb the wavelength range emitted by the flash radiant heaters, used previously.

Only with the invention of the ceramic HSR heater is energy saved, including during running time.

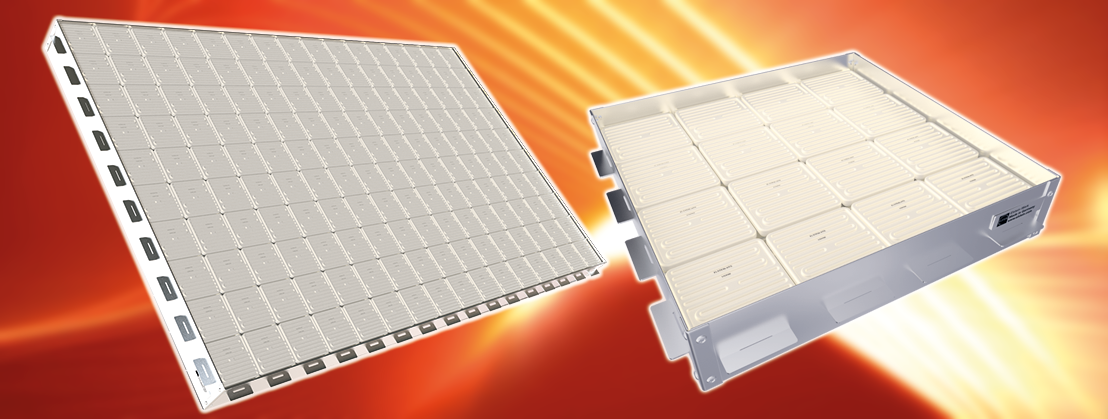

Stainless Steel Heating System

In comparison to aluminium, heating panels made of stainless steel have a low thermal conductivity and a low thermal expansion coefficient, and are more resistant to corrosion and acids.

In addition to these purely material-related advantages, Elstein BSI stainless steel heating panels are based on a completely new construction principle which compensates for thermally conditioned longitudinal expansion without mechanical stress.

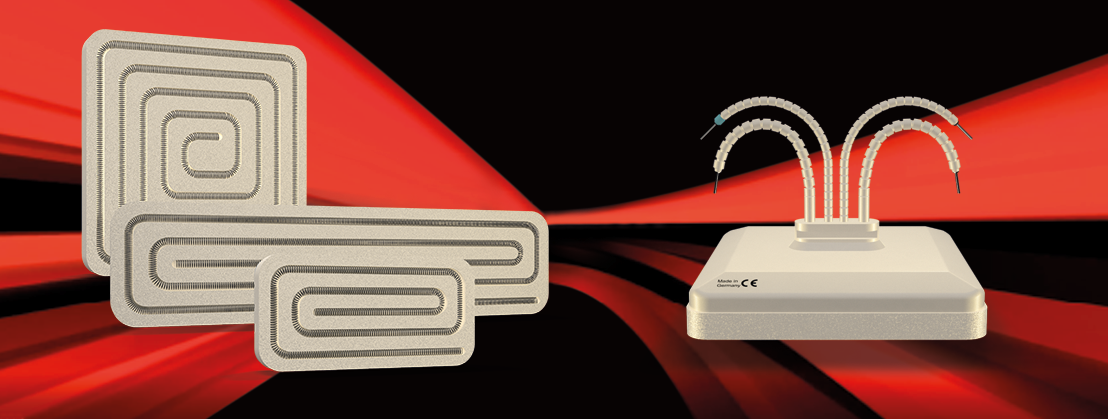

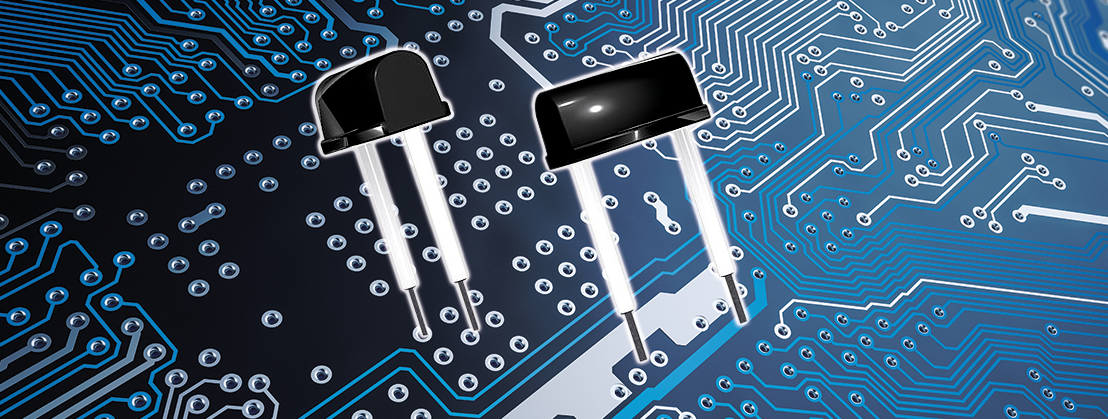

Microsystem Heater

With a volume of less than 2 cm³ and a weight of 3 grams, this heater looks like a structural component for electrical circuitry. In fact, the MSH is an IR heater that produces temperatures of over 800°C within the smallest of areas.

As an individual heater it emits heat on one small spot. A group of them can, among other things, selectively heat the edges of curved shapes.

Heating Tunnels

Increased requirements regarding energy efficiency and temperature-focusing for heating cylindrical items, led to the development of this heating element with a high-quality, corrosion-resistant stainless steel housing and integrated thermal insulation.